Blog & News

Full Belly Files | New Year’s Resolution: Know, and Support, Thy Farmer

Full Belly Files Newsletter, January 9 2026, by Matt Kettman

Full Belly Files serves up multiple courses of food & drink coverage every Friday, going off-menu from our regularly published content to deliver tasty nuggets of restaurant, recipe, and refreshment wisdom to your inbox.

New Year’s Resolution: Know, and Support, Thy Farmer

Put your money where your mouth is this year, starting with Pico’s lunch series; plus, stories you may have missed.

Though its popularity is no longer peaking, the winemaker dinner developed a tried-and-true format for hosting a meal that is both indulgent and educational.

The basic formula — for those who haven’t managed to attend one over the past three decades or so — is that the winemaker introduces each course by explaining the chosen wine for that dish, often with the chef also chiming in on the cuisine. Diners leave full of both food and information, often leading to lasting relationships with the wineries and restaurants involved.

(If that piques your interest, check out this “Soul & Soil” dinner at Finch & Fork on January 29 with Chef John Vasquez and winemaker Jessica Gasca from Story of Soil.)

An auxiliary benefit of that format — which still works well for winemakers, by the way, so long as there are enough paying customers in attendance — is that restaurants are applying a similar approach to the farmers, ranchers, and fishermen who fuel their menus. In this age of ever-curious, sustainably minded eating, why not let these frontline food producers share some of the limelight and tell us more?

I’ve advocated for this myself over the years in this column. One call-to-action in my piece about the last farmers’ market in the old location even led to this Lotusland benefit dinner last year, when I was able to ask questions of the highly engaging Jacob Grant of Roots Organic Farm.

It’s great to see more “farmer dinners” — for lack of a better name — pop up around our community. Doing them best right now must be Pico in Los Alamos, which launched their Know Thy Farmer lunch series in February 2022 with Motley Crew Ranch and Sea Smoke Wines.

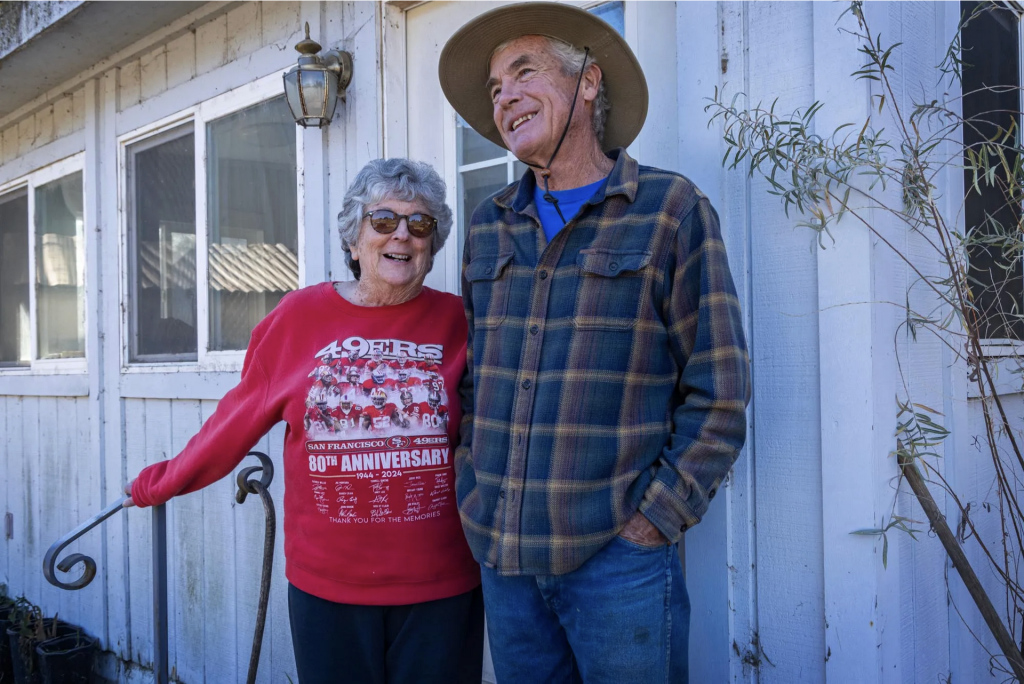

Kali Kopley (right) with Carla Malloy at last year’s Elder Flat Farm Know Thy Farmer lunch.

Know Thy Farmer is driven by Pico co-owner Kali Kopley, who develops the connections and crafts the menus for these monthly events. She keeps them intimate, with a max of 40 people seated at two long tables, and affordable, at $50 for three courses, dessert, and pairings from Lumen Wine, which are made by Will Henry, Kopley’s partner in business and life.

“The inspiration for Know Thy Farmer was to create a gathering where guests could meet a local farmer and learn about their passion, story, practices, and about daily life on the farm,” she said. “These lunches are my vision to meet your neighbor and learn where your food comes from.”

Last year, we previewed last August’s Elder Flat Farm showcase and I mentioned December’s Luretik Olive Oil lunch, but the next two really caught my eye: Mighty Cap Mushrooms on January 18 and Winfield Farm on February 7.

Even casual readers of Full Belly Files must recognize my growing fascination with mushrooms, and Mighty Cap out of Paso Robles is the Central Coast’s most prominent commercial grower of edible fungi. (I’m long overdue for a story on Solvang’s Wolfe Family Farm, so maybe I’ll finally get on that this year.)

For their event next Saturday, Kopley plans to make a consomme of maitake — which is Mighty Cap owner Chris Battle’s favorite mushroom, she said — as well as a mushroom and bacon salad. She may also make a mushroom cassoulet with Lompoc beans or a lion’s mane fritter. “My head is full of tasty mushroom ideas,” she admitted.

Winfield Farm’s subsistence bounty | Credit: Matt Kettmann

The menu is even more adventurous for the Winfield Farm lunch on February 7. You may remember Winfield Farm from this newsletter I wrote about Bruce and Diane Steele moving from gourmet pigs to subsistence crops in November 2024, which was slightly expanded into this January 2025 cover story. The Pico lunch will highlight both eras of Winfield, including the succulent heirloom pork that Bruce pioneered and the hardy grains that he’s now championing.

“I was going to make cold soba noodles with my hand-harvested durum wheat and have Kali roll it out in her pasta roller,” said Bruce, who serves them with a dipping sauce. Added Kopley, “Bruce is going to teach me how to make durum wheat pasta, and I will teach him how to roll out pasta on a fancy Italian pasta machine. Mostly Bruce will be teaching me!”

For the main course, they are thinking about a sausage dish, either with polenta made from the hand-ground purple maize that Bruce grew or a black caviar lentil from Rancho Gordo. For dessert, Bruce may make a batch of Korean-style acorn starch jelly called dotori-muk to create a dark chocolate pudding that can fill with profiteroles produced from a mix of homegrown and store-bought flours.

Bruce Steele threshes buckwheat in the middle of Winfield Farm. | Credit: Matt Kettmann

As guests enjoy the food and Lumen pours, Kopley and the Steeles will discuss Winfield Farm’s subsistence farming techniques and how they utilize native grains. She is fired up, exclaiming, “I think this lunch is going to be the best ever!”

For more tickets to Pico’s Know Thy Farmer events — including Mighty Cap on January 18, Winfield Farm on February 7, and Figueroa Mountain Olive Oil on March 28 — click here. If you’re interested in learning about future Know Thy Farmer events — or about Pico’s 10-year anniversary party next month — sign up for their monthly newsletter at the bottom of this page. For more info on Pico, see losalamosgeneralstore.com.

Retreat

Any land worth having was someone else’s land before you. Of course a house needs less land than a farm, and you can divide land, plant houses and write off the handprint of the farmers who tended the fields. Money isn’t everything, but as the houses got closer to the family farm, the taxes for what the farm was worth had more to do with the price of housing than the value of the crops it might produce.

Taxes went up until Grandpa had to move on and we sold. We all moved north and kept at it with cattle and alfalfa instead of oranges and lima beans. The old place had tack rooms with old harnesses hanging. There was a forge and a place to work metal, the draft stock needed shoes. A can of carbide was in the corner and we could cook up acetylene, although I was too young to start cutting metal with more than a saw. But we sharped nails with the grinding wheel and made spears.

Moving north meant the old horse drawn equipment, the steam equipment and that which was too big to truck went to scrap or over the edge into the barranca. The new equipment yard in Oregon was modern for the times, but bigger just kept getting bigger, and by the time Oregon came apart the auction was a bloodbath . We put too much faith in those machines and they really broke hearts, and still it goes on — one farm sale to the next.

Anyway I always wondered how it would be if we hadn’t mechanized, if we stepped back in horsepower towards minimalism rather than the grandiose. A hoe, maybe a couple of battery electric tools that could be replaced with something smaller and cheaper, in a pinch. But here it is, the end of expansion. Here we are and bigger is about to lose.

My time is arriving, although the auction was the end a long time ago. The old farm went down and I picked up a grub hoe. Grandpa had good advice I have tried to live by. He drove horses, fixed stationary combines, got big and got crushed. He said, “Buy water, not land. “ He said I shouldn’t expect to make any money farming. I took his advice, bought riparian water rights, a little land with it, and I have never been surprised that I didn’t make money farming. The houses are getting closer, everything else seems like it’s further away.

On the land

I guess I’m trying to prove something proven millions of times thousands of years ago.

There will be villages bringing in grain again someday, but for now it’s just one old man on his hands and knees and not so romantic. I harvest with a nice sharp pair of kitchen shears. Handful by handful, I carefully place the wheat into a big cardboard box all lined up and neat so I can, one handful at a time, pull it out again to thresh. If it’s nice and neat it works better. My threshing floor is a big tarp set out in a field where it can catch lots of wind. It doesn’t rain here, so at least I have time to make it a daily half hour of work threshing and winnowing until I get through everything. Hand milling on 10,000 year old technology isn’t all that difficult, but it takes me an hour to get enough flour for one nice round loaf of bread. I haven’t timed the harvest and threshing times, but per pound they go faster than the hand milling. Harvest is time sensitive, whereas the milling can wait months, so milling can be something to while away winter hours.

I choose techniques that require zero steel. Yes, my grubbing hoe is steel, and my hand shears too, but they can both be converted back to stone, as they were in the Neolithic.

I have come to believe the quern stone was the invention that enabled civilization.

My project is to grow grain crops by hand with a hoe, but my project also involves milling the grain on a rhyolite metate that I pecked into a working form. I can mill about two cups of fine flour and another two cups of bran and semolina in an hour. The last part of the project has been capturing a sour dough starter and baking various sour dough loaves. Rye, rosemary acorn and spelt are some of the grains I have grown and used in the small loaves that I bake.

I know this has all been done before, and they tell us from such humble beginnings we built cities. Growing, threshing and winnowing fifty pounds of wheat isn’t difficult . There are plenty of crops far more fickle than wheat. My 50lb. red durum crop came off eight rows together in a thousand sq. ft. of garden space. Red durum is very productive and far easier than spelt to process into clean grain.

Milling time is a bit of a constant, like how much time it takes to hoe a given area of garden. Other chores, like dehulling grain, can be fairly quick or frustratingly slow depending on the grain you use. There is no secret technique, the hand tools are timeless: the quern, the mano, the wind.

I can tell you it’s easy, there are thousands of cultures to prove that a peasant with some seed and a quern stone can feed a family – lot of time or timeless tradition.

But we have largely forgotten making stone tools, or winnowing grain. Pecking Querns has probably always been a bit of a specialty, and farthest from a skill your digital assistant will ever help you with. Grind stones require a venture into our past, and finding your first effective quartzite hammer-stone and whacking it against another rock is a real walk into our past. Our hands remember quickly. The stone you want comes round, and another season of grains too, and the years slip away, until your work is part of what always was, like your tools and your time here on the land.

Red durum wheat in field

Stone milling tools ~ Quern stones

Bruce documents his knowledge and accomplishments in subsistence farming on Substack. His Substack URL is Bruce Steele – Substack substack.com This is his latest post about stone milling tools.

***

Stone milling tools were on Aunt Shirley’s porch in Moorpark . They were mostly stone bowls and pestles used for preparing acorns. They came from the bean fields when a plow would turn them up. Aunt Shirley put dirt and succulents in them, one bowl on each step.

The bowls and the rocks they came from have come to into my life, one bowl or metate (quern stone) at a time. I started pecking bowls with a steel hammer and chisel, but smoothing them has always been done with a mano, and usually that same mano would eventually marry with the bowl, the surfaces worked together for a perfect fit.

For me pecking a metate without steel tools has been long dead lessons relearned. Saddle Querns were produced by every civilization prior to steel tools. The Quern made civilization possible. Wheat really wouldn’t have done us much good without a Quern. But when steel chisels came along so too did the Querns, and steel chisels enabled bee hive style round milling stones to be created and they replaced the old saddle shaped ones that served us for at least 8,000 years before steel and rotating mill stones.

I use three stones: The big relatively long and flat stone that will be shaped into the saddle, a river rock that is shaped like a rolling pin, and a quartzite hammer stone. The mano (rolling pin) needs to be of a harder stone than the saddle, and you can start to hit the saddle with it to remove bit by bit a crumble of grit. As the mano repeatedly hits the quern it smooths the end of the mano, and as the quern takes shape so does the mano. The quartzite hammer stone is smaller than the mano and it is used to peck surfaces after the larger mano has roughed it into shape. Also as you put more and more work into your quern, more delicacy is required to avoid breaking it. So a lot of the final shaping is with the quartzite hammer stone.

An interest in milling tools led to an interest in milling acorns and crops we humans milled in the past. Acorns kinda led to pigs, but that is a different story. Milling acorns is relatively easy because they are soft and can be milled wet. Wheat and grains are milled dry and require different tools than the bowl and pestle used for acorns.

Quern stones need to be hard because nobody wants grit in their flour. Our ancestors didn’t like grit either . Knowledge about what stones work is easy enough if you copy what stone our ancestors chose. Granite or basalt querns are common. You can look into what stones were used locally at a natural history museum near you.

So after pecking my quern and grinding some rice to clean it and rid it of grit, I tried grinding some dehulled spelt . I used a #50 sieve to sift the flour . The results are nice light colored flour with no grit.

[My interest has grown] From pecking stone bowls to preparing acorns, from hundreds of pounds of foraged acorns to pigs. From wheat to pecking a quern: Egg noodles, soba noodles, breads, cream of wheat from the bran, desserts.

It is easy enough to rake up 500 pounds of acorns and dry them for storage. With nothing more than a grubbing hoe and a hand sickle, one man can grow, harvest and process 50 pounds of wheat, another fifty pounds of spelt and several hundred pounds of corn on about a half acre and still have room for plenty of fresh vegetables.

A hoe and some stone milling tools are the basic tools that enabled our distant relatives access to enough food to support a village. Those same tools, without mechanization or steel, still can provide.

Once upon a time, the lords took the quern stones from the peasants. They were taking their freedom to farm untaxed. If all the grain had to go to the manor’s mill to get flour for bread, everything could be tallied and taxed. There is some freedom still in gardening and milling without anything but human power.

A stone hoe is still a future project but I suspect it would work as well as the steel grub hoe I currently use.

Red Durum Wheat, 50 pounds finished grain from a 1,000 sq.ft. garden space and a grub hoe. Threshed and winnowed by hand. Mostly milled with an electric mill but walking back is optional, right?

Wheat field at Winfield Farm

Threshing wheat by hand

Wheat bundles in field

Growing from seed with no fossil fuel

He grew everything from seed with no fossil fuel. He’s rightly proud of his endeavor, all direct seeded and weeded with a grub hoe.

@winfield_farm is eating plenty high on the proverbial hog these days!! The afternoon sun shines light on the abundance— agriculture as art!

POTLUCK CONVERSATION

(Purple garden majesty)

I was at a potluck that several local gardeners hold where they can show off their cooking and tell stories. I was bragging about my garden and showed some photos. Another gardener asked me, “What do you do with it all? “

I had a pat answer, which is: the pigs are always eager customers. The question has lodged in my brain, however, and I keep trying to rationalize — an acre of grains, red wheat, white wheat, spelt, barley and corn, along with lots of Cole crops from the winter garden – because the “what do you do with it all “question is also a “why do you do it all,“ or at least in my head it has morphed into that.

Mostly I grow grains for dry storage, but I also try to keep two years supply in the drying shed and always keep seed for next season. I can answer “what I do” better than “why I do it,” because every season for many years, I have squirreled away the fall bounty. Finding the tools to process at very small scales is a parallel pursuit, and finding recipes are corollaries to the harvest abundance, but usually only pecking at the volumes waiting in the shed.

There is an advantage in growing grains in that they can be accurately weighed and entered in some sort of calorie ledger. “What is enough” is a valid question and it bothers me a bit, but “how much is possible” nags at me too, but in a positive kind of way.

The garden is growing very big these days, but it is spring and the winter was mild. I keep planting and so I keep increasing how much garden I need to keep cultivated. It can catch you and overwhelm you as the heat turns on, too many weeds rooted too deeply. So, you cultivate between rows at the first hint of newly germinated weed seeds. Bare ground between rows is eventually shaded by crops, but lots of cultivation while it is bare is essential.

What is possible, what tools, what seed, when to plant, those things I know. How to do it without lots of power, and again, what is possible? In that I have some confidence, borne by years and years of gardening. Still, it is a solitary pursuit and has been for most of the thousands of hours gardening in my life.

So why so much? I don’t really know, but I imagine somewhere in my gene line an answer lies. It wasn’t always a full larder, and no I can’t compensate for the distant past, but an empty belly has a very long memory, I think, or no memory at all.

Bruce

Mini bike cultivator

by Bruce Steele, originally published on Substack

I combined an 8” hoss tools oscillating hoe with an electric mini bike. It is both fun to use and utilitarian. It is a one off and I am always happy when a google search doesn’t reveal anything similar.

This electric cultivator together with an electric tractor are the only power equipment I use to farm/ garden. My farm has had a 5.8 kW solar array for ten years and two powerwalls for a little over five years. My irrigation, refrigeration and home electric needs have been 88% solar powered for about decade . The solar and batteries have paid back the purchase price of my system . I still have grid supplied power but my electric bill averages about $30 a month .

I have been raising market pigs for the last decade and the solar system has supplied all the energy to keep my eight chest freezers operating. I will admit any transport of product or feed has been done with internal combustion . I am tired of feeding fossil fuels into trucking in a business that is not much better than break even. My farm has produced about a million dollars of pork but my days as a swineherd are dwindling.

I had a garden , a farm stand and a few years as a market gardener before the pigs came along. The pigs were initially intended to feed on all the vegetables that kept going into compost from the farm stand but they kinda took over. After a decade however I would like to restart my former vegetable stand with a goal to measure productivity of an electric farm.

How many calories can one farmer and electric tools produce? Just like my solar/ battery system paid back its purchase price with reduced electric bills how long does it take to produce enough vegetables to repay the cost of the new tools? If there is some way to calculate the embedded energy costs of producing the whole system of solar electrics and farm tools then how many food calories need to be produced to repay the embedded fossil fuel costs? These are valid questions and they have quantifiable answers.

I will be recording weights of vegetables and grains produced but farming entails cover cropping and soil building with legumes and added compost. These projects require energy and are necessary for healthy soils and productive crops. The energy expended for soil building can only be recouped with vegetables and grains produced but some accounting for the work required to maintain soil health is still necessary . Furthermore soil building and adding organics are one of the few ways we have at our access to pull atmospheric carbon back into the soil.

I do hope my project draws the attention of some agriculture college or other farmers interested in ag electrics. The tools are off the shelf available and I have a few acres to farm.

So zero fossil fuels for farm equipment, fertilizer, farm electric needs or irrigation and to the best of my abilities to avoid fossil fuel transport of production.

Winfieldfarm

Buellton Ca.

From Gourmet Pork to Subsistence Farming

Why Buellton’s Winfield Farm Will Stop Raising Mangalitsa Pigs in Favor of Sheer Survival

By Matt Kettmann | Photos by Macduff Everton

Originally published in The Santa Barbara Independent, January 9, 2025

Buellton, California; Bruce Steele, with his hoe in vegetable garden, Winfield Farm | Credit: Macduff Everton

At a time when supporting honestly raised, regionally grown, sustainably minded food is on the lips of every self-respecting restaurant lover, why is it essentially impossible to make a stable living off of working the land?

In the case of one Buellton farm, which rose to prominence raising the exact kind of gourmet pork that source-conscious chefs seek out, the rigamarole of regulations combined with high costs and low market prices is forcing them out of the pig business. Instead, they’re shifting to subsistence farming as a model for survival, exploring how harvests of buckwheat, barley, amaranth, acorns, spelt, squash, corn, cactus, and many other crops can support modern human existence.

“This is not just my story,” said Bruce Steele, who owns Winfield Farm with his wife, Diane Pleschner-Steele, together raising the country’s largest registered breeding herd of swallow-belly Mangalitsa pigs for more than a decade. “It’s all of us.”

Over the next few months, they’ll be winding down operations, selling off the last of their once-celebrated chops, ribs, and sausages to restaurant chefs and home cooks. Similar woes are being felt all across California, from the nearby Motley Crew Ranch — which just opened a meat market in Buellton but is no longer raising large animals — to J&R Natural Meats, which shut down its two Paso Robles butcher shops last year, and the famed Llano Seco Meats in Chico, which closed in 2023 after 162 years of selling to top restaurants.

“What has happened is that human technological and physical infrastructures for regional food systems have essentially disappeared,” explained Shakira Miracle of the Santa Barbara County Food Action Network (SBCFAN). “Our small-scale producers are the ones who are suffering.” She’s been working with farmers on potential remedies for their compounding woes since 2021, and hopes to open Lompoc’s federal prison as a new regional processing site in 2026.

That’s already too late for Winfield Farm. “This doesn’t work,” lamented Bruce on the porch of his drying shed one morning last fall as bright sunshine recharged the solar-powered property. “Nothing you can do will ever work,” he continued, to which Diane added the caveat, “in California.”

Winfield Farm’s Bruce Steele feeds some of his remaining Mangalitsa pigs. | Credit: Macduff Everton

Bruce’s farming saga goes back to the 1860s near Moorpark, where generations of his family tended beanfields that evolved into orange groves. When he was at Camarillo High, he’d visit his grandparents and extended family in Oregon, where they’d moved to raise cattle and alfalfa while practicing plenty of traditional food preservation techniques.

“They were all babies of the Depression,” said Bruce, who is 70 years old. “That had a huge mental impact on those who went through that time.”

He enjoyed the lifestyle, especially gardening with his Aunt Shirley. “I always wanted to be a farmer — that was maybe my first mistake,” he laughed. “My grandfather said, ‘If you ever want to make any money, don’t do this! If you buy land, buy water!’ ” (It’s no coincidence that Winfield Farm has riparian water rights along the Santa Ynez River.)

But Bruce also loved fishing, and marine biology classes led him to pursue hard-hat diving as a career, originally intent on working the deepwater oil rigs. No one took him seriously at 18 years old, so he wound up back in Ventura County, settling into life as an urchin diver in 1973.

The route from his house in Camarillo to Anacapa Island and back was easy, and he’d stash away $100 a day after

covering his current and future expenses, selling urchin for 8 cents a pound. (Today, the popular spiny treats can fetch $10 a pound.)

“It was like a banker’s hours!” he exclaimed. He kept at it after moving to Santa Barbara in 1976, building a life and well-known garden on the Mesa, and was still diving for urchin regularly until about a decade ago.

“In my heart, I’m still an urchin diver,” said Bruce, who was a major player in the development of the rules and zones that govern fishing today. “I still have a permit.”

Diane Pleschner-Steele and Bruce Steele outside of their home. | Credit: Macduff Everton

In 2000, he used urchin income to purchase 30 flat, occasionally flooded acres between the Santa Ynez River and Highway 246, just west of Buellton, and named it Winfield Farm after his dad’s middle name. Bruce and Diane — who worked for two decades as the head of the nonprofit California Wetfish Producers Association — started farming a wide variety of common row crops like tomato, melon, and squash, selling them at their farmstand every summer.

The farm generated a massive amount of compost, which is where the pigs come in, as they’re ideal for eating such scraps. But not just any pigs: the almost-extinct Mangalitsa breed from Hungary, discovered after the Iron Curtain fell with only around 100 pigs remaining.

Like the Ibérico breed of Spain — whose jamonistas are credited with rediscovering and restoring the Mangalitsas — these pigs produce incredibly marbled, intensely flavorful meat. “They’re the only pigs other than Ibérico that can be called pata negra,” said Diane of the top-shelf “black foot” designation animals, which Bruce feeds a special malted barley spiked with chestnut powder. “If you feed tannins to these pigs, it changes the fat composition,” he said of such nut powders, citing recent research out of Serbia.

Winfield Farm welcomed its first swallow-bellied Mangalitsas in 2013, and the herd grew exponentially in size, reaching about 120 at peak pig. Many restaurants were buying the meat, particularly the late Jeff Olsson of Industrial Eats as well as, on occasion, Barbareño, Barrelworks, and Chef Cameron Ingle when he was at Pico in Los Alamos. (Today, Niner Wine Estates in Paso Robles is the most dedicated buyer.) The Ritz-Carlton Bacara’s chef at the time was also a steady customer, and that’s where Bruce was planning to supply pork for an event about eight years ago when he got a standard inquiry about his liability insurance.

He quickly learned that California regulators frowned on farms that raise both vegetables and pigs. “Pigs and vegetables?” they told him. “You’re canceled!”

According to Bruce, the issue goes back to an E. coli outbreak in the Salinas Valley. “No one really knows what happened,” he said. “But they blamed the pigs.”

Such concern makes sense on the industrial farming scale, but applying such broad regulations to a tiny farm that only sold produce to neighbors? Bruce and Diane felt like unintended targets. It wouldn’t be the last time.

Suddenly, since pork made marginally more income than vegetables, Winfield Farm was out of the veggie business.

Bruce Steele threshes buckwheat in the middle of Winfield Farm. | Credit: Macduff Everton

Meanwhile, the pork business got harder. COVID killed restaurants for a time, although the direct-to-consumer market briefly exploded. The war in Ukraine, which was a major global supplier of grain, caused feed prices to skyrocket, doubling Winfield Farm’s cost from around $30,000 a year to more than $60,000. Said Bruce, “You can’t just double the price of your already expensive meat.”

Problems arose close to home as well. “Ultimately, my butcher quit,” said Bruce of when the primary Central Coast butchery service, J&R Natural Meats in Paso Robles, shut down operations last year.

That loss triggered processing problems all across the regionally raised meat realm, although the recent opening of Sinton & Sons in J&R’s place should bring a bit of relief for some ranches. Pigs, however, remain particularly challenging — even more so for Winfield’s large, hairy Mangalitsas, which require special equipment. Unlike many other states, which allow pork to be distributed so long as it’s processed according to each state’s health codes, California regulations require pork to attain federal health standards before being sold broadly.

The U.S. Department of Agriculture (USDA) rules are onerous since they’re aimed at industrial pig farms, but Bruce and Diane feel like they don’t make much sense for small farms like theirs. He said that this is the one law that, if changed to allow state-level approval before distribution, could potentially save California’s small pig farmers.

Instead, the route from Winfield Farm to a plate for this Mangalitsa meat runs from Buellton to Fresno, where the animals can be sparged, all the way down to Glendale, where the USDA-certified Schreiner’s Fine Sausages handles the bacon, ham, sausage, and other smoked meat products. (Smoking is even more highly regulated.) Such transportation is expensive and not very eco-efficient, undermining the critical argument for buying local.

On top of that, California voters in 2018 passed an animal welfare proposition to clean up factory-sized meat operations. The new rules about spacing — which finally went into effect last year after much legal wrangling — didn’t impact operations at Winfield Farm at all, but still created costly confusion and a bunch more hoop-jumping for small farmers. Not only that, but Bruce said that the proposition’s main point of keeping animals out of cages was ultimately relaxed anyway.

Pig farmers like Bruce Steele go a bit cross-eyed when navigating the web of regulations. | Credit: Macduff Everton

“The bottom line is that it didn’t change anything on my farm,” said Bruce. “It’s paperwork that serves no purpose, developed by a bunch of well-meaning people who didn’t have any idea of what the pig business was about.”

“We are also getting out of the pig business,” said Marko Alexandrou of Motley Crew Ranch, located just a few miles west of Winfield Farm on Highway 246. “Until we have a legal slaughter facility in Santa Barbara County, I refuse to continue raising large animals. It’s unfair and inhumane to have to drive them two to three hours north for harvest, saying nothing about the carbon footprint.”

Marko and his wife, Cassidy Alexandrou, have also grappled with the effects of Prop. 12, which they say are burdening small farmers while massive operations have a “free pass” to raise animals under those controversially confined conditions. “Our pigs have so much space that the law is irrelevant, but I still have to register and have someone from the state come by and tell me that my five pigs are okay on five acres,” said Marko.

SBCFAN’s Miracle said that Prop. 12 is a great example of good intentions leading to lots of unintended consequences. “People meant well, but because people are increasingly disconnected from where their food comes from, they do not understand that we have regional producers of crops, seafood, and meats, and then we have this catastrophically different scale of centralized industrial agriculture,” she explained. “It’s the difference between commodifying food, and growing, catching, and raising food that’s going to add net benefits to your health and wellness, to the community, and to the net economy.”

That these distinct versions of agriculture receive the same treatment is baffling for her and so many. “Santa Barbara County, with all its uniqueness, is just a recipe for what is best for us in terms of what we can do with food,” said Miracle. “The challenge is that we need more county, state, and federal lining up on the regulatory side so they’re not contradicting one another.”

When asked about these concerns via email, the state sent back a fairly canned response, and did not respond when emailed follow-up questions. Steve Lyle, the California Department of Food and Agriculture’s director of public affairs, explained that the mission of the state’s Animal Care Program is “to serve animal agriculture producers and California consumers by promoting and protecting the welfare and care of animals in agriculture in order for Californians to have access to food that is sourced from humanely and sustainably raised animals.” And to do that, Lyle said, “All farms are held to the same standards.”

So instead of larger animals, Motley Crew — which just opened a meat market in Buellton after spending $200,000 and 18 months to do so — is sticking to poultry and rabbits, both of which can be legally harvested on the farm and sold direct-to-consumer. “Everyone wants local, organic, regenerative meat, but the reality is that California makes that really hard, and Santa Barbara County makes it nearly impossible,” said Marko. Like Steele, he believes California should allow state rather than federal rules to dictate allowing processing here, and that regulations should be relaxed for tiny ranches such as his.

“The likelihood of those things happening is minimal,” he admitted. “We’ve been advocating for it for 10 years, others longer. The money, the space, and the will are there, but the regulatory process is not.”

The one glimmer of hope on the horizon is opening the federal prison in Lompoc as a USDA-certified meat processing facility. The current push for this came out of a working group that SBCFAN called together in August 2021, though the process has taken a lot more time than most involved assumed.

The prison’s vocational training programs long included butchering courses, and Lompoc once provided meat to many other prisons in the system. That shifted when dairy became more popular, but now there is a willingness to reinvigorate the meat processing facility and make it available to regional ranchers as well.

“We are now in the process of finishing the pre-development of this enterprise, which we hope to launch in 2026,” said Miracle, who needs to raise about $4 million to pay for the final costs. “If we are able to raise the capital needed to finish up the facility, we will launch sooner.”

The plan is not only to open the facility for processing beef and pork, but to also build a network of supply chains so that ranchers can more easily sell their meat into the market as well. “From there, on day one, we will be able to offer USDA-certified beef and pork processing,” said Miracle. “That’s a game-changer for a lot of reasons.”

For Winfield Farm, though, the writing was already covering the walls. “Every single thing is expensive to do here,” said Bruce, noting higher wage and fuel costs than other states. “Restaurants won’t pay you what it costs to do this.”

It was time to ditch the pigs.

Buellton, California; Bruce Steele feeding his pigs, Winfield Farm | Credit: Macduff Everton

Bruce and Diane’s interest in subsistence farming goes back to before COVID. On one New Year’s Eve, he told her that they’d do “The Challenge,” which involves living off of their own land and not going to the store for an extended period of time. They made it a month, and that was without any proper planning. They ate a lot of eggs and acorns.

He started exploring the crops needed to do it for a longer stretch, planting grains, more fruits, and hearty vegetables that last longer on their shelves. He’s learning how to grow and process each of them — farming more than a half-acre all by himself, mostly with a rusty hoe — and, perhaps most importantly, how to turn them into food.

“If you can’t figure out how to cook it and make it taste good,” they both agreed, “you’re wasting your time.”

He’s learned to use the wind to winnow white-blossomed buckwheat, that “you need to crush the hell out of” spelt, and that one ear of corn amounts to a batch of cornbread. A later attempt at The Challenge lasted about three months, but they’re preparing to go all in, even though they admit the cuisine can become a little bland. (I suggested more hot and pickled peppers.)

Left: A bounty of subsistence crops. Right: Acorns are on the menu. | Credit: Matt Kettmann; Macduff Everton

“We’re on the verge of doing it right now,” said Diane, explaining that they’re dining subsistence-style “almost every night.” The night before I visited, for instance, they ate a tomato and cassoulet bean soup with pork meat, followed by a squash pie for dessert.

The whole project — from a solar-powered tractor to the gritty handwork to the knowledge unleashed in ancient grains to using every part of their land to survive — struck me as fascinating, perhaps only eclipsed by the fact that no one seems to care. When I asked if Bruce had any acolytes out at Winfield Farm learning these ways, their response was blunt and disheartening: “No one wants to know.”

Diane’s dream is to document what Bruce is up to, while he would like to see more farmers use his land to explore similar crops and invest in the wisdom they offer. Said Bruce, “It’s gonna matter.”

But Winfield Farm pork is not dead yet. They still have about four months of meat to process and sell, which anyone can buy straight from the farm. To do so, visit winfieldfarm.us.

Editor’s Note: An earlier version of this article ran in November 2024 in Full Belly Files, Matt Kettmann’s weekly food & drink newsletter. Read that version here and sign up for his newsletter here.

Buellton, California; Bruce Steele, Winfield Farm

We’re Delighted to Announce: We’ve Got HAM!

Thanks to our new association with Schreiner’s Fine Sausage in Glendale, we’re now able to produce Smoked Boneless Mangalitsa Ham!

We’re offering Winfield Farm Mangalitsa ham in two styles:

The specialty of the house:

Boneless Mangalitsa Black Forest Brand Ham

Shreiner’s dips boneless Mangalitsa ham in caramel #29 to produce an amazingly succulent, flavorful treat!

Get 4, 5, or 6 pound packs (Price $23 / pound) now from our limited supply of Mangalitsa Black Forest Brand ham at our online market.

We’re also offering:

Smoked Boneless Mangalitsa ham

Get 5 or 10 pound packs (Price $18 / pound) of Smoked Boneless Mangalitsa ham now at our online market.

#####

ANNOUNCING A NEW “PARTNERSHIP” and A NEW PRODUCT (with more to come!)

Our hunt for a USDA certified smokehouse that could process our Mangalitsa bellies into hickory smoked bacon led us to Schreiner’s Fine Sausages. Family-owned, Schreiner’s has been located in Glendale since 1952. (Glendale is about 2 ½ hours south of Winfield Farm.) Wally Schreiner is now the third generation to run the family shop, which still smokes all of its own meat, under USDA inspection. Wally said of course he could smoke our bellies, since our pigs are slaughtered and butchered by USDA certified establishments. But we would need our regular butcher to slice and package the bellies for bacon. (This extra step is now needed because our regular butcher no longer smokes product inspected by USDA – a requirement for resale.)

The saying ‘when one door closes, another door opens’ is so true — and serendipitous. We discovered a veritable treasure trove of unique and very tasty offerings at Schreiner’s — and the opportunities are virtually endless!

To wit, we’re delighted to announce that, in addition to Mangalitsa bacon smoked by Schreiner’s, we’re now offering Smoked Mangalitsa Sausage – Hungarian style. Ground Mangalitsa pork is seasoned with salt, paprika, black pepper, onion, and garlic. The encased sausages are smoked, fully cooked, then packaged and frozen. The flavor is sensational!

The introductory price on our online Mangalitsa Market is $18 per pack of 5 sausages.

A package of Hungarian Style Mangalitsa sausage straight from the freezer. These weiners are so good, we often eat them straight out of the package, cold.

The future of our new relationship with Schreiner’s is bright! Schreiner’s can make Mangalitsa Kielbasa (Polish sausage), black forest ham, and many other specialty items for Winfield Farm. We’ll keep you posted on progress.

Meantime, we encourage you to try Schreiner’s smoked Mangalitsa sausage – Hungarian style.

We love these weiners, and hope you will too!!

Note: Smoked Mangalitsa Sausage – Hungarian style is now available for online ordering!

Panchetta from Winfield Farm Mangalitsa

According to Wikipedia, Pancetta is salt-cured pork belly meat.

In Italy, it is often used to add depth to soups and pastas. Foodies worldwide value Pancetta’s flavor profile. Two basic types of pancetta are arrotolata (rolled) and stesa (flat).

For cooking, pancetta stesa may be cut into cubes for use in carbonara pasta or pizza, as is typically found in central and southern Italy. In northern Italy, pancetta arrotolata is commonly served rolled and thinly sliced, and consumed raw (although guanciale, cured jowl meat, is generally considered more traditional).

Photo credit: Nachoman-au – CC BY-SA 3.0, https://commons.wikimedia.org/w/index.php?curid=522168

Photo credit: Nachoman-au – CC BY-SA 3.0, https://commons.wikimedia.org/w/index.php?curid=522168

The art of pancetta, as with all salume products, is in the curing process. Here at Winfield Farm, we are pleased to offer an exclusive treat: Mangalitsa pork pancetta cured by Alle Pia Fine Cured Meats.

Following their family tradition, and inspected by USDA, Alle Pia first marinates the Mangalitsa bellies in vacuum-sealed bags for three weeks, to infuse special seasonings, including rosemary, garlic, juniper berry and sea salt. As part of the curing process, the bellies are then removed from the bags and hung in a temperature-controlled chamber for 30 days.

You can taste Mangalitsa magic by special ordering Mangalitsa pancetta (stesa). Email us directly at Winfield Farm (dplesch@gmail.com). Supply is limited (not listed on our online Mangalitsa Market).

$35 / lb Pieces average approx. 4-5 pounds each